Today’s society continues to change at a dizzying pace, and it is called the VUCA era, where it is difficult to predict the future. VUCA is an acronym for Volatility, Uncertainty, Complexity and Ambiguity, making it difficult for society and business to predict the future. It means situation. To cope with this VUCA era, it is effective to increase *agility. By conducting analysis using process mining, you can eliminate the *3Ms (MURI, MUDA, MURA) and find clues to increase agility. Here we present an analysis that uses process mining to discover all 3Ms.

*agility: As a business term, it stands for the management and organisational agility that is essential to respond quickly to dizzying environmental changes. It is a concept that encompasses the speed and efficiency of decision making, the flexibility of team formation and the division of roles, and is attracting attention as a keyword for organisations and individuals to survive in an era of high uncertainty and disruption.

*3M (Muri, Muda, Mura): a concept originating in Japan that is cited as an element to be eliminated when promoting rationalisation and efficiency in production management and business operations. Further details are given below.

What is Business Agility? Discover the Framework for Business Agility

Typical 3Ms (Muri, Muda, Mura) in the manufacturing industry

The basis of operational improvement in the manufacturing industry is the elimination of the following 3Ms (Muri, Muda and Mura).

- Muri (overburden): a situation where workload exceeds capacity.

- Muda (waste): refers to a situation where the workload is less than the capacity. Surplus to be removed, e.g. extra production, extra operations included, etc.

- Mura (fluctuation): refers to a situation where a mixture of both Muri and Muda occurs over time.

Process Mining is good at analyses that focus on business patterns and process elapsed time. By allowing analysis to focus on time, it is possible to first identify irregularities. Next, by looking at the actual process patterns drawn and the time taken for each process, it is possible to identify Muri (repetitive tasks and backlogged work) and Muda (excessive personnel and duplicated work). From this point, we will introduce specific use cases to ensure transparency of work patterns and analyse the causes of longer times for all processes.

Use case

Making business processes transparent

Business processes, including modern manufacturing operations, are very complex and pass through various sensors, IT systems and departments; the area in which an employee is involved is part of the business process and not all of it is known. This situation can lead to mistrust, lack of flexibility and inequality between those involved in the operation. Only those who know the actual processes completely and in detail can contribute to increased agility.

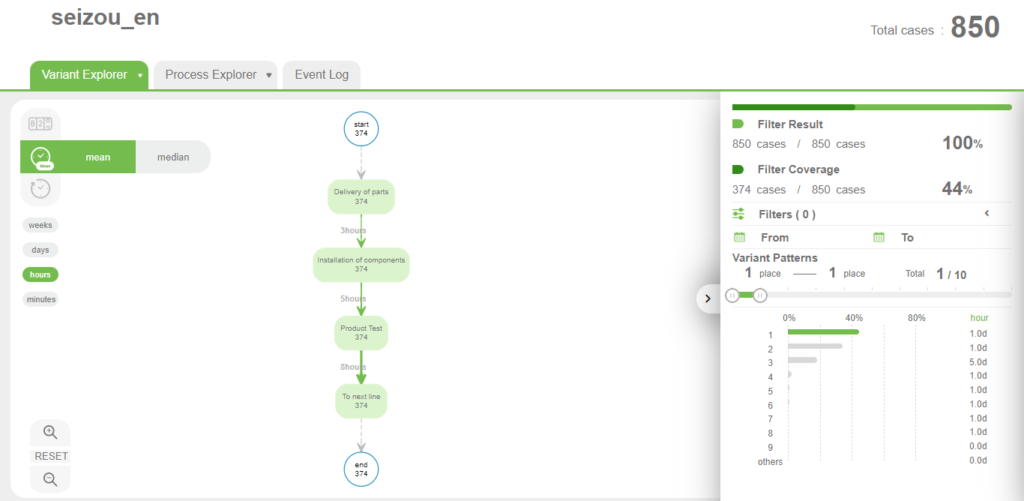

As an example, let us analyse the assembly process of an automotive component. The first step is to collect, draw and observe the data related to the manufacturing patterns, as shown in the process diagram below. In this way, the entire operation can be reliably captured as facts in the form of data, or analysed in an exploratory manner to discover irregularities.

Extending a series of operations

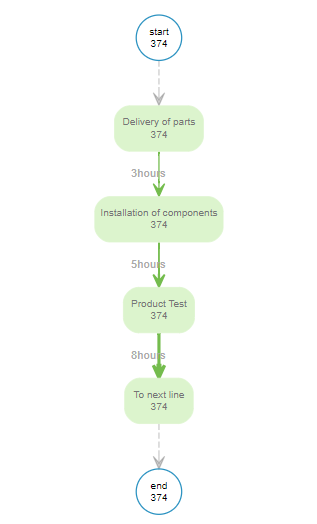

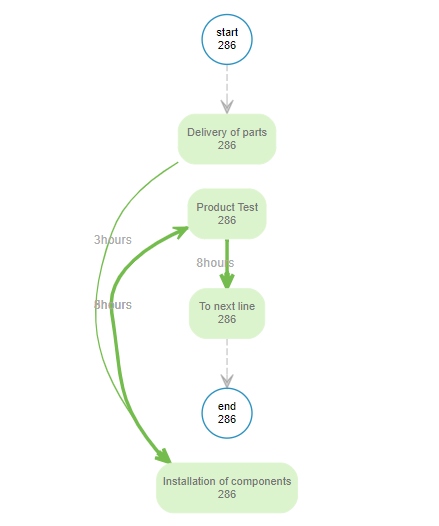

Previously, transparency was achieved by collecting data and drawing process diagrams. The exploratory analysis shows that when comparing Variant 1 and Variant 2, the lead time of Variant 2 is 16 hours longer than Variant 1. As Variant 1 is a standardised business process, we can expect problems to be hidden in Variant 2, so let’s compare the processes in Variant 2.

Variant 1 is shown on the left and Variant 2 on the right. The difference between the two variants is whether or not the process is repeated. The Variant Explorer shows that the process in the repetitive part takes an extra 16 hours of lead time.

In this analysis of the long time taken for a series of operations, we found that one of the causes of Muri was the occurrence of repetitive operations. In addition to detecting Muri, process mining can also be used to detect other types of waste, such as the possibility of waste due to overstaffing when process times are abnormally short despite the same work pattern.

Process mining analysis for manufacturing is useful for discovering Muri and Muda.

In this article, we introduced process mining analysis to discover the 3Ms (Muri, Muda and Mura) as a way to improve agility to cope with the VUCA era. Process mining analysis can be performed by starting the analysis with transparency and exploratory analysis to discover Mura, and then finding the causes of Muri and Muda from the discovered Mura.